In the realm of Printed Circuit Board Assemblies (PCBA) inspection, the precision and reliability of visual inspections are paramount. Utilizing the right equipment can significantly enhance the inspection process, ensuring the highest quality standards. Here, we explore six essential pieces of equipment that are integral to effective PCBA visual inspection operations.

VJ Electronix X Quik III

The VJ Electronix X Quik III revolutionizes the process of counting and managing PCBA components. It excels at counting even the most challenging reels with an impressive 99.8% accuracy rate, ensuring that inventory management is both precise and efficient.

- Ultra-fast results

Processes components, scans barcodes, and updates inventory in real-time to your MES/ERP in under 10 seconds, optimizing resource management.

- In-line operation

Features two automatic shutters enabling pass-through automation and can be integrated with robotic reel handling options.

- Versatile counting

Capable of single (15in) or quad (7in) counting, recognizing odd shapes, overlaps, and various sizes.

Vision Engineering EVO Cam II

The Vision Engineering EVO Cam II is a full HD digital inspection system designed to provide detailed and high-speed visual inspection. Its small footprint makes it adaptable to various work environments, ensuring that space constraints do not hinder inspection quality.

- High-definition imaging

Produces full HD images at 60 frames per second with no lag, ensuring real-time inspection accuracy.

- Advanced zoom capabilities

Features a 30:1 zoom ratio and 16x-150x optical zoom for detailed component examination.

- Versatile viewing

Configured with an oblique viewer for direct and angled inspections, maintaining focus while rotating around fixed points.

Vision Engineering Lynx EVO

The Vision Engineering Lynx EVO offers unparalleled magnification capabilities, making it ideal for precision inspection tasks. Its ergonomic design allows operators to use the microscope comfortably, even with glasses or safety goggles, enhancing productivity and reducing adjustment time.

- High magnification

Provides up to 240x magnification with optional accessories, with a 10:1 zoom ratio offering 6x-60x magnification.

- Precision focusing

Coarse and fine adjustments enable fast and precise focusing.

- Enhanced hand-eye coordination

Allows users to maintain natural hand-eye coordination, critical for detailed inspection, rework, and repair tasks.

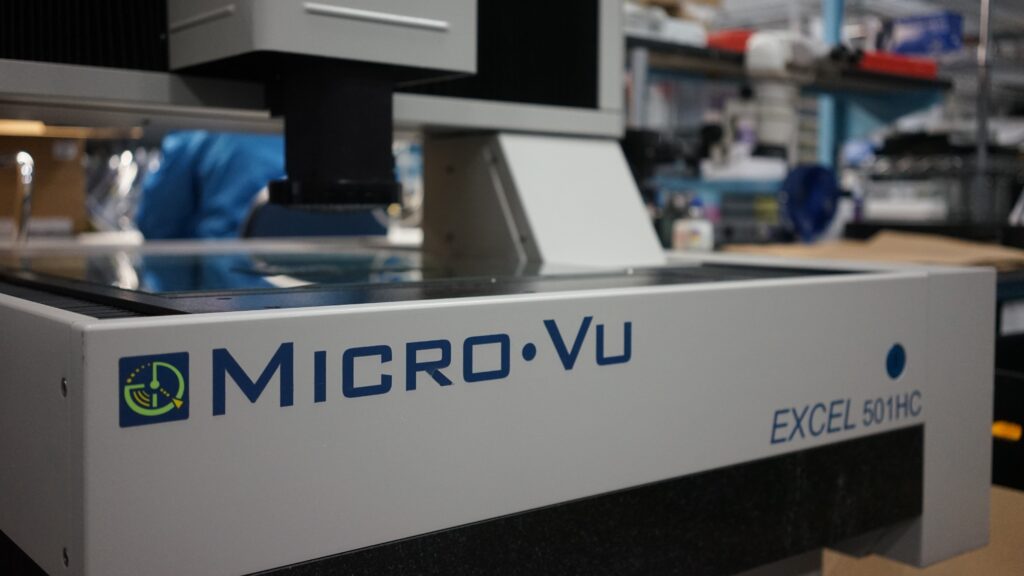

Micro-Vu Excel 501HC

The Micro-Vu Excel 501HC is a high-resolution camera-based system designed for fast, accurate measurement and inspection of various parts. Its robust design accommodates large parts and multiple fixtures while maintaining a compact footprint, making it versatile for different inspection needs.

- High-resolution imaging

Provides vivid images with programmable optical and digital zoom.

- Large part accommodation

Measures parts up to 2.5 meters long and up to 100 kilograms.

- Advanced sensors

Integrates high-speed vertical distance measurement sensors for enhanced scanning capabilities.

The ScanCAD machine is essential for ensuring precise and accurate visual inspections of PCBAs. This system utilizes advanced scanning technology to provide detailed inspections, ensuring that every aspect of the PCB meets the highest standards.

-

- High-resolution scanning

Captures detailed images of the PCB for thorough inspection.

- Defect detection

Identifies defects such as misalignments, missing components, and soldering issues.

- Real-time analysis

Provides immediate feedback for process adjustments, enhancing overall inspection efficiency.

- High-resolution scanning

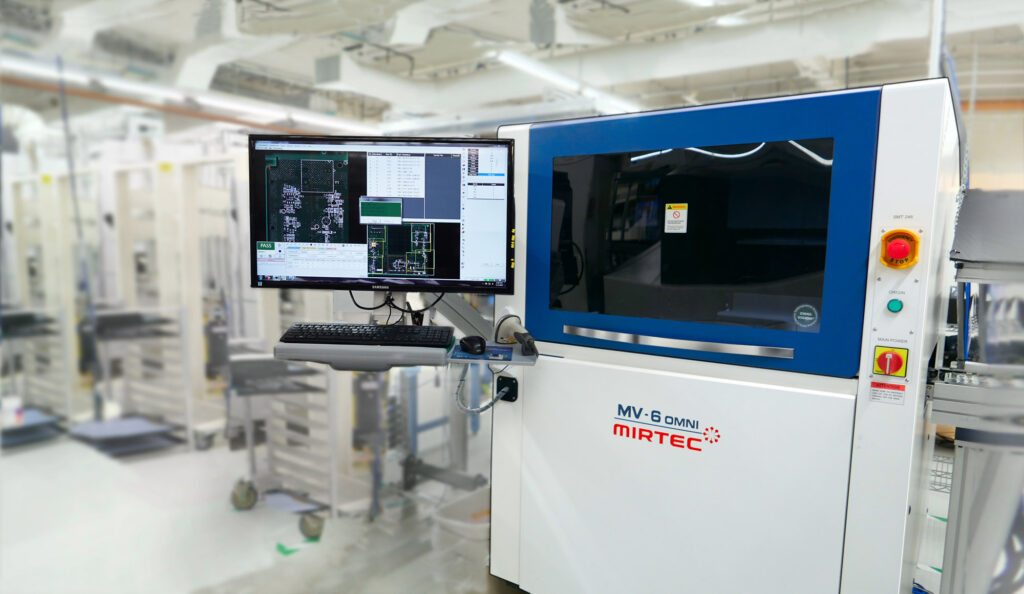

Mirtec AOI – Automated Optical Inspection

The Mirtec AOI machine is a cornerstone of modern PCB inspection, utilizing advanced optical technology to enhance visual inspections. This system provides precise component placement and solder inspection, increasing accuracy, repeatability, and efficiency.

- High-resolution imaging

Captures detailed visual and 3D images with advanced CoaXPress and Blue DLP technology.

- Comprehensive inspection

Offers precision optics and side-view capabilities for thorough inspection from multiple angles.

- Programmable flexibility

Enhances operation with a multi-focus system and intelligent automation for seamless integration.

The ViTrox V9i CI is a crucial asset for manufacturers aiming to elevate their PCB quality control, combining advanced technology with seamless integration and powerful inspection capabilities.

- Fast and reliable inspection

Multi-angle views with rule-based and self-learned algorithms for comprehensive inspection, covering issues like coating splash, bubbles, and foreign objects.

- High precision and traceability

Integrated with a Cobot, camera-read barcodes, and and external reader for precise inspection and component-traceability

- Powerful performance and flexibility

Intel Core i9 processor, 64GB RAM, and 1TB NVME M.2 storage, with inspection speeds of 30cm²/s, making it a high-performance solution for demanding production environments.

Each of these advanced tools plays a vital role in enhancing the accuracy, efficiency, and reliability of PCBA visual inspection operations. By integrating these technologies, manufacturers can uphold stringent quality standards and ensure that their products perform flawlessly in the field.